It has many advantages over building materials, including:

Being light

Very easy and fast delivery and installation

Reasonable price in terms of cost reduction

Cost-effective construction

Save energy

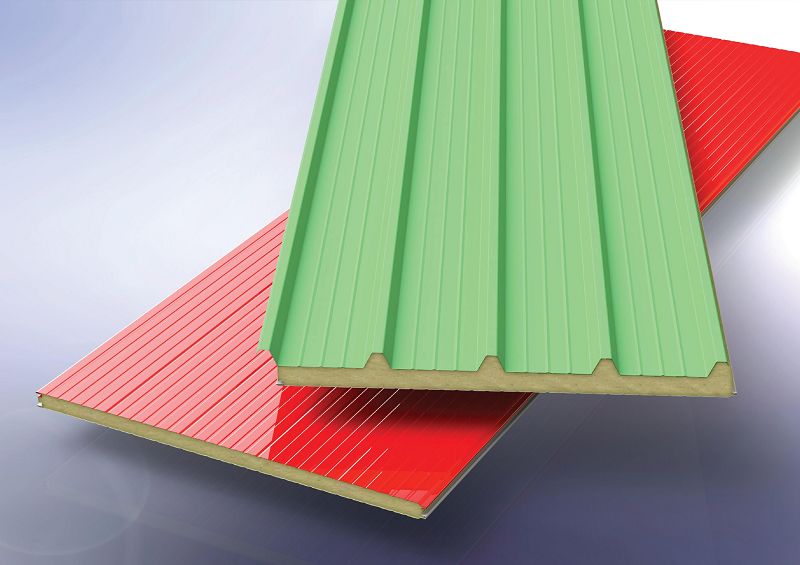

The sandwich panel is a structure, which consists of several interconnected layers. Sandwich panel layers each have physical and mechanical properties and are specific to a place with a specific application, but in general, three types of wall sandwich panels, ceiling sandwich panels and refrigeration sandwich panels are used.

Mumtaz Janoob Refrigeration Industries Company is an active group in the field of consulting, design, production and implementation of various types of sandwich panels, including roof sandwich panels, wall sandwich panels and refrigeration sandwich panels.

Foam sandwich panel type:

Polyurethane (PU) with a density of 2 + 40 kg per cubic meter

Type and thickness of sheet used:

Alloy sheet (zinc and aluminum), galvanized and pre-painted aluminum with a thickness of 0.45 to 0.7 mm

Applications of sandwich panels:

It consists of three layers, two steel sheets and the middle core as insulation. Sandwich panel sheets:

1.Aluminum sheet:

Thin sheets are said to be flexible, bendable, and because they are soft, easily wrapped around objects. Its special feature is anti-corrosion.

It is a sheet with anti-corrosion properties, light weight and strong and strong connection.

Iron is steel dipped in metal

It is a sheet that is made of aluminum, zinc and silicone that does not suffer from corrosion and rust. Insulation foams are fireproof. The most important of these foams is polyurethane foam, which is stronger or slower than other insulating foams. Aluzink sheets are also widely used. There are two types of raw and colored sheets available in the market. Raw sheets are more expensive than kiln colored sheets

Including light weight, very easy and fast delivery and installation, reasonable price, is economical in terms of reducing construction costs, and saves a lot of energy. Sandwich panel is a structure, which consists of several interconnected layers. Each layer of sandwich panel has physical and mechanical properties and is specific to a place with a specific application. But in general, two types of wall sandwich panels and ceiling sandwich panels are used.

Technical specifications of sandwich panel sheets

The choice of a type of sandwich panel depends on the conditions of the type of structure or building, which includes interior and exterior walls and roof. Also, the indoor temperature and climate of the area is another important factor that should be considered in choosing a sandwich panel. . Sandwich panels are unique. Provides high thermal performance, continuity of insulation, minimal air leakage and elimination of cavity density between wall and ceiling structures, the result of using this structure provides us with a safe and beautiful building. These benefits are very useful in high humidity and coastal environments to cover these areas. Galvanized sheet and rolled sheet are available in rolls

The thickness of these sheets can be: Aluzink sheet starts from 70 cm to 130 cm, aluminum sheet from 0.2 mm to 2 mm for construction purposes.

دفتر مرکزی:

۰۷۱۳۷۷۳۴۷۲۴

طراحی و اجرا سردخانه:

09176591823 – 09174144743

تجهیز فروشگاه:

09174447906 – 09174144525

طراحی و اجرا کانکس و ساندویچ پنل: 09174447940 – 09174144743

ممتاز تبرید جنوب در زمینه تولید یخچال و فریزر های صنعتی و تجهیزات فروشگاهی، تولید انواع ساندویچ پانل سقفی و ساندویچ پانل دیواری و ساندویچ پانل سردخانه ای فعالیت دارد. طرح و اجرای سردخانه در شهر شیراز بندرعباس بوشهر ،کرمان و جنوب کشور با در اختیار داشتن متخصصین و کادر فنی مجرب در زمینه طراحی و تولید و همچنین با بکارگیری مواد اولیه مرغوب اقدام به تولید محصولات با عالیترین کیفیت از نظر دقت ، ظرافت ، زیبایی و استحکام نموده است.

طراحی وب سایت: رایین رایانه

[vc_row][vc_column]